5 priorities to consider for drop hazards.

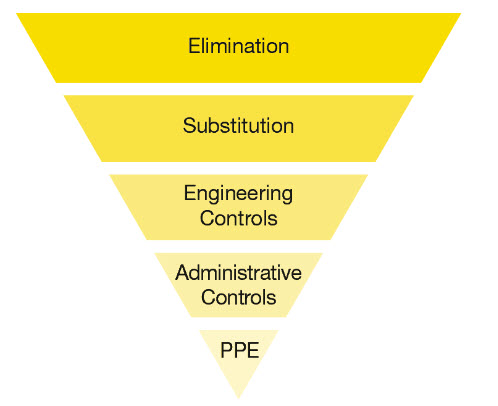

The five-step hierarchy of controls serves as a fundamental framework for effectively preventing drops hazards and safeguarding personnel. When devising strategies to ensure the protection of individuals, it is essential to follow this hierarchy.

The hierarchy of controls is a widely recognized principle in various industries, including oil and gas, power generation, and manufacturing. It outlines the prioritized steps that should be taken to address health and safety hazards, making it the cornerstone of any comprehensive health and safety approach, particularly when focusing on drops prevention.

Let's explore the five priorities that constitute the hierarchy of controls:

1. Elimination: The first step is to assess whether the risk can be completely removed. For instance, during facility design, careful consideration should be given to potential overhanging hazards like lights and speakers. Not all of these fixtures may be necessary, so eliminating them can eliminate the associated risks. Similarly, minimizing lifting maneuvers, which are often a significant cause of drops incidents, should be a key priority for plant managers. Designing facilities that reduce the frequency of lifting operations can make a significant difference.

2. Substitution: If complete elimination is not feasible, the next step is to identify measures to minimize the risk. Operators should explore options like repositioning fixtures that pose overhanging hazards or utilizing different types of lighting.

3. Engineering controls: Installing physical barriers such as nets, barrier systems, pouches, and "red zone mats" can provide effective protection. For example, safety securing nets can enclose fittings like CCTV cameras, preventing them from falling if their fixtures become loose. Solid barriers can be added to railings to prevent tools and objects from falling through gaps.

4. Administrative controls: Implementing measures like establishing "no-go" zones, developing collision checklists, and conducting toolbox talks can significantly mitigate drops hazards. These administrative controls aim to enforce procedures and reduce human errors that could lead to drops incidents.

5. Personal protective equipment (PPE): While it should be the last line of defense, providing personnel with appropriate PPE is crucial. This ensures that in the event of a falling object, serious injuries and fatalities are minimized. Offering suitable PPE demonstrates a commitment to the safety and well-being of personnel.

CONTACT US

HEAD OFFICE

QTEC TECHNOLOGY CO., LTD.

ADDRESS: 457 BOND STREET ROAD, TAMBOL BANGPOOD, AMPHUR PAKKRED, NONTHABURI 11120 THAILAND

LINE: @qtec-technology

Email: e-sales@qtec-technology.com

TEL: +66(2) 583 8300

Facebook: QtecTechnology